News

Application of pulse dust collector

With the progress of bag dust collector technology, especially the emergence of new filter materials, the application range of pulse cloth bag filter is more extensive. At present, the most widely used in production, the highest market share of large bag dust collector is the pulse dust removal, Large-scale high-efficiency bag dust collector is one of the symbols of the development of modern dust removal technology. It has high dust removal efficiency, especially the fine dust trapping effect is better. In recent years, the improvement of filter material, the automation of dust control and the optimization of body structure performance have provided technical guarantee for the development of bag dust collector.

The development trend of shot blasting machine

In today’s manufacturing world, precision and efficiency are paramount. Shot Blasting Machines have become a key technology in surface treatment processes, offering unmatched advantages across a wide range of industries. From cleaning metal parts to enhancing surface finishes, shot blasting plays an essential role in improving product quality and durability.

Shot blasting machines are used to clean, strengthen, or polish metal and other surfaces through high-velocity streams of abrasive materials. This process is typically used to remove contaminants like rust, old coatings, and scale from metal surfaces, preparing them for further treatment or coating. It is also used to increase the surface profile of materials for better adhesion during painting or coating.

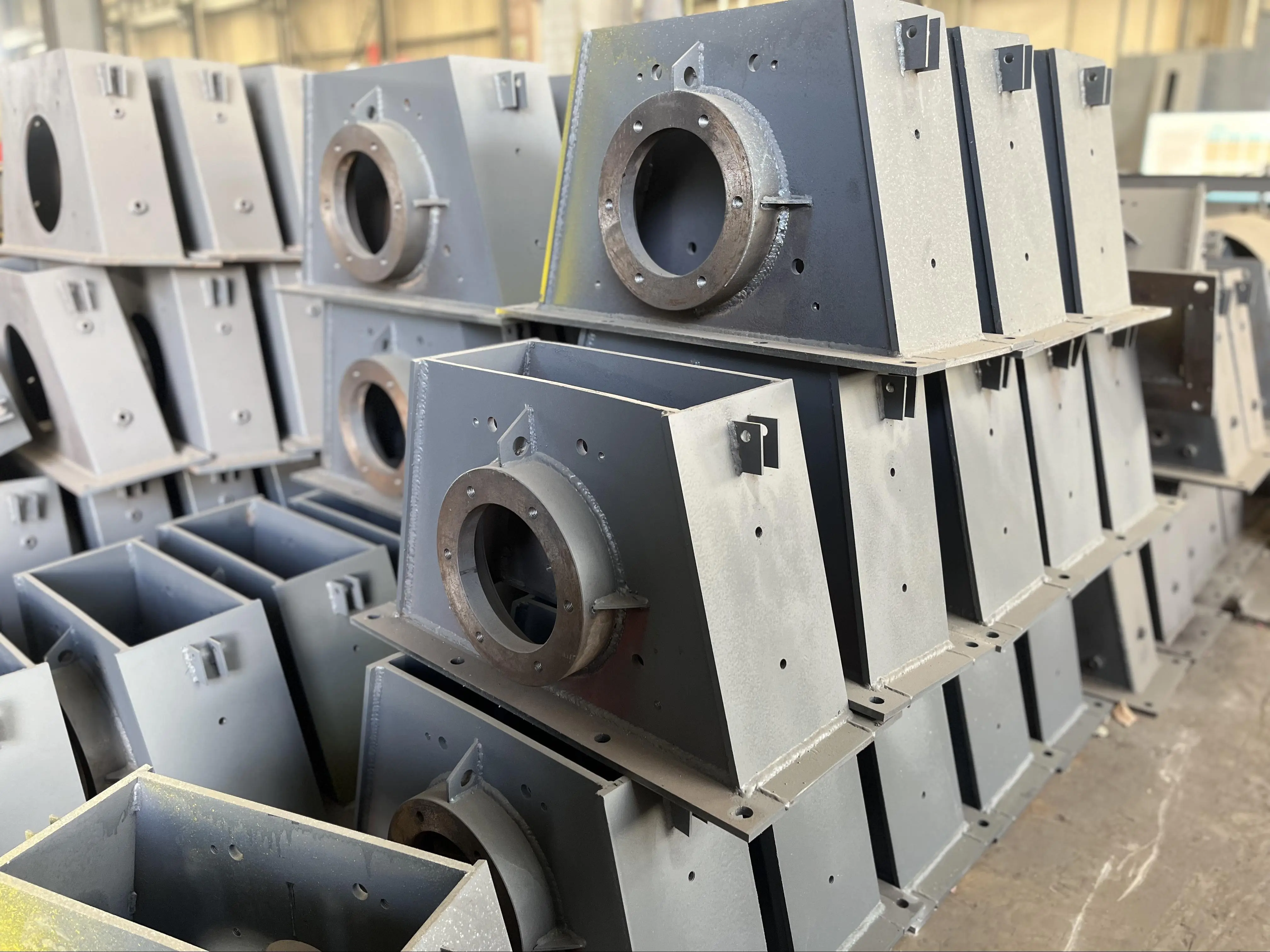

How to avoid the common faults in the operation of the shot blasting machine

The working principle of the Shot Blasting Machine is to clean or strengthen the surface of the workpiece by throwing the projectile at high speed.Shot blasting machine mainly consists of shot blasting machine、Projectile circulation system、Workpiece conveying system and dust removal system, etc.working hours,The shot blast throws the projectile at high speed onto the workpiece surface,The impact of the projectile can remove the oxide on the surface of the workpiece、rust、Welding slag and other impurities,At the same time, the surface of the workpiece produces compressive stress,Improve the fatigue strength and corrosion resistance of the workpiece.However, the following common phenomena often occur in the operation of the shot blasting machine.

How to understand the application of rotary table shot blasting machine

Rotary Table Shot Blasting Machine is an efficient industrial shot blasting cleaning equipment, it is mainly used to remove dirt, rust and other impurities from the surface of the part. The working principle is that the steel ball is thrown evenly to the cleaning part surface by a high-speed rotating turbine to achieve the effect of rust removal.

The crawler shot blasting machine application

Crawler Type Shot Blasting Machine, suitable for all kinds of parts surface cleaning,All kinds of metal castings surface sand cleaning,Surface rust removal of ferrous metal parts,Blunting of burrs and burrs on the surface of stamped parts,The surface treatment of forgings and heat treated workpieces, as well as the removal of oxide on the spring surface and the grain refinement on the surface can be achieved through the shot blasting process of this series of equipment.

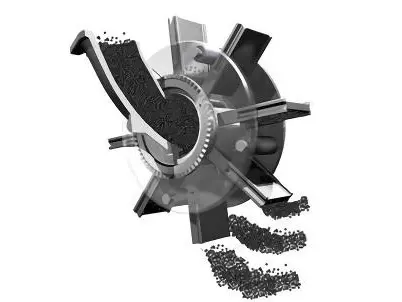

About the force and application field of drum shot blasting machine

The working principle of the Drum Shot Blasting Machine is to throw the projectile to the workpiece which is continuously turned in the cylinder through the high-speed rotating impeller,Thus to achieve the purpose of cleaning the workpiece,To be specific,The Drum Shot Blasting Machine has a high-speed rotating impeller inside,The impeller generates centrifugal force and wind force during rotation,Accelerate and eject the projectile,Strike the work surface,Achieve cleaning and strengthening effects.

The importance of shot blasting machine.

The main functions of the shot blasting machine include the removal of surface dirt and oxide layers、Rust removal、Clean and dust、Remove welding slag and heat treatment skin、Improve surface roughness and finish、Enhances surface hardness and wear resistance、surface preparation、Improve the appearance quality of the workpiece、Workpiece strengthening、Improve coating adhesion、Improve fatigue life and concrete surface treatment.

Application advantages of stainless steel belt

Stainless Steel Belt Shot Blasting Machine is a surface treatment equipment used to treat stainless steel belts,It is mainly used to remove impurities such as surface dirt, oxide, grease and dust,To improve the surface quality and coating quality,The device strikes the surface of a stainless steel strip with a high-speed projectile projectile,Thus achieving the effect of cleaning and strengthening.The stainless steel belt shot blasting machine uses a shot blasting device to shoot high-speed projectiles onto the surface of the stainless steel belt,Impurities such as dirt, oxide and grease are removed from the surface by the impact force of the projectile,This treatment doesn't just clean the surface,It can also improve the mechanical strength and wear resistance of the stainless steel belt.

About the force and application field of drum shot blasting machine

The working principle of the Drum Shot Blasting Machine is to throw the projectile to the workpiece which is continuously turned in the cylinder through the high-speed rotating impeller,Thus to achieve the purpose of cleaning the workpiece,To be specific,The Drum Shot Blasting Machine has a high-speed rotating impeller inside,The impeller generates centrifugal force and wind force during rotation,Accelerate and eject the projectile,Strike the work surface,Achieve cleaning and strengthening effects。

Understand the application advantages of stainless steel tape

The Online Steel Strip Shot Blasting Machines are specifically designed to used in hot rolling annealing pickling process for carbon steel, alloy steel, or stainless steel strips. It is to remove the oxide skin from the stripe surface. It is an indispensable equipment for hot strip steel production line. All branches of steel producing and manufacturing industries use surface finishing processes. Semi-finished or finished products must be free from rust, scale or contaminants for any subsequent operation.