Crawler shot blasting machine installation precautions

The track type Shot Blasting Machine should be gradually installed before operation, the proper installation can ensure the normal operation of the machine.

Users have to prepare concrete according to the local soil first, and then check the horizontal and vertical levels of the ground by a level before install the machine.

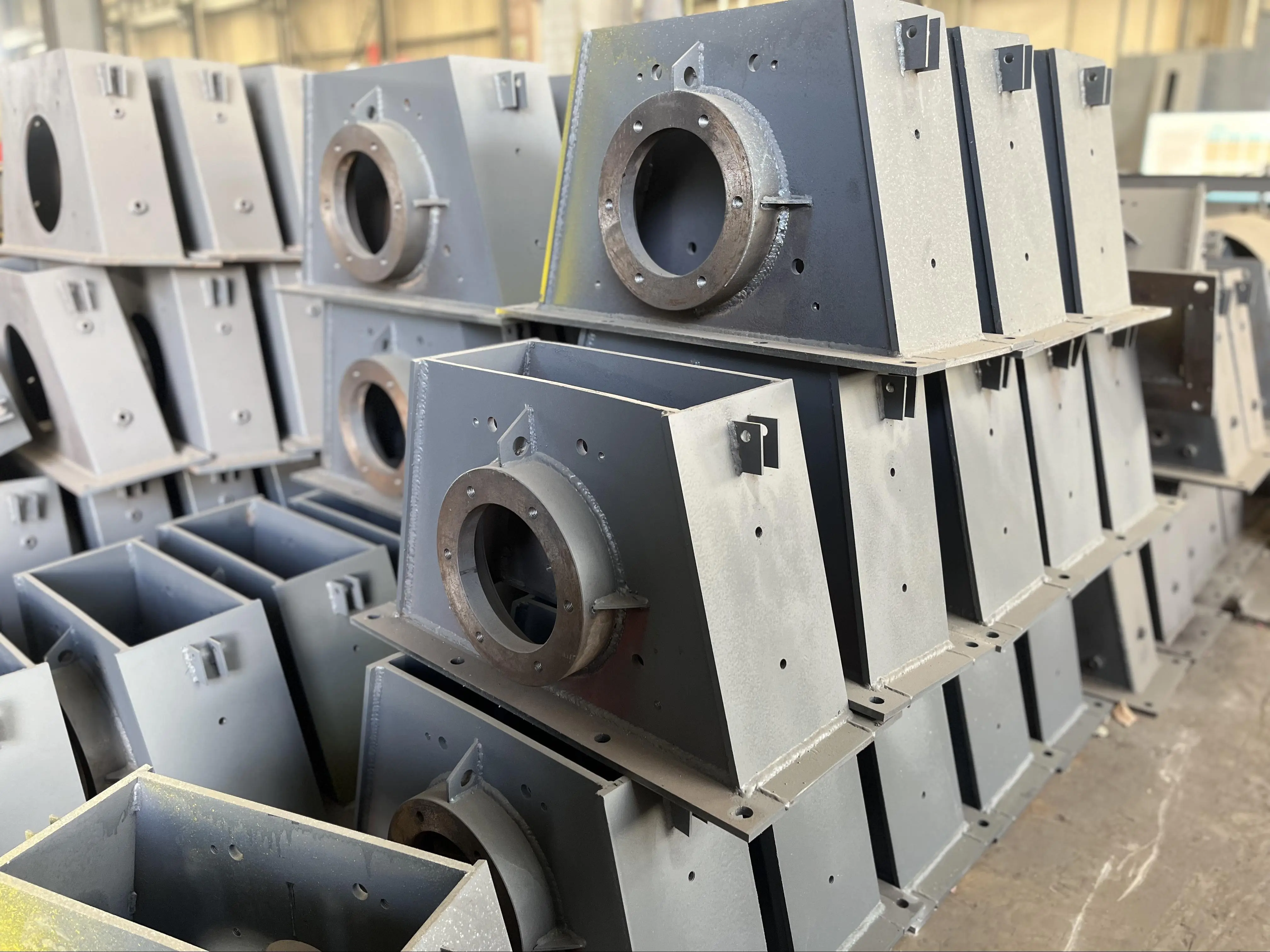

The machine has assembled the shot blasting chamber and turbines into one before leaving the factory. When receiving the goods for installation, bolt the elevator with the elevator part on the shot blasting chamber. When installing the bucket elevator, attention should be paid to adjusting the upper end of the active pulley bearing seat to keep it level and avoid belt deviation. And then bolt the separator and the upper part of bucket elevator.

Install the shot supply valve on the separator, insert the shot recovery pipe into the steel pipe behind the shot blasting chamber, and connect all the pipes according to the dust removal system diagram. After the separation of waste, users can prepare a waste box for disposal the wastes by separation.

Crawler type shot blasting machine features advantages:

The track type shot blasting machine combines domestic and foreign technology, low noise and its compact structure, it is widely used in large and medium batch production as rust removal and strengthening shot blasting treatment.

The crawler type shot blasting machine uses a cantilever centrifugal turbine, which increases the life of the machine. In addition, the international technology pulley used on crawler shot blasting machine, greatly increases the efficiency of the shot blasting machine and reduces the labor force.

The bag filter type dust collector is used in the crawler shot blasting machine, which makes the dust emission lower than the national standard and ensures the excellent working environment of the workers.