Hook type shot blasting machine working principle

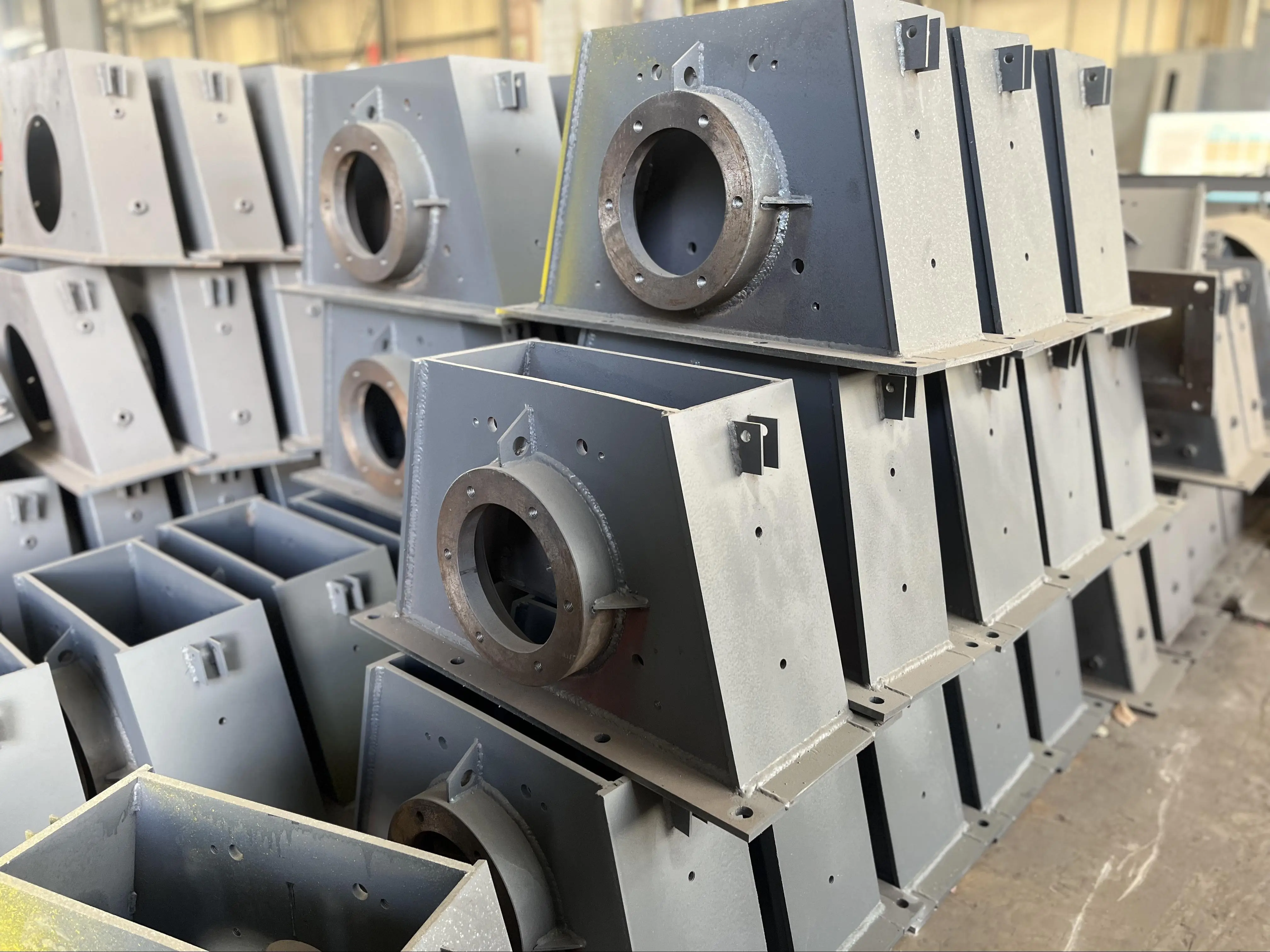

Hook type Shot Blasting Machine The shot blasting room is used to place metal workpieces and shot blasting wheels,Usually consisting of a protective plate to prevent splash;The shot blasting wheel is driven by an electric motor to rotate at a high speed.The projectile is sprayed onto the surface of the metal workpiece;The shot collecting system is used to collect the shot in the shot blasting room to ensure its recycling. The dust removal system is used to purify the air in the shot blasting room and remove dust and impurities generated during the shot blasting process.

Hook type shot blasting machine is widely used in metal manufacturing industry, including shipbuilding and repair, automotive industry, aerospace, bridge construction, pipeline treatment and other fields.In these fields, the hook type shot blasting machine is used to clean the welding slag, paint, rust, etc., on the surface of the workpiece, improve the surface finish and corrosion resistance, and provide a good foundation for subsequent processing (such as spraying, electroplating).

In addition, the advantages of the Hook type shot blasting machine include good cleaning effect, high production efficiency, cost savings and a wide range of application.It can effectively remove the impurities on the surface of the workpiece, improve the surface finish and roughness, and enhance the hardness and corrosion resistance of the workpiece.At the same time, the hook type shot blasting machine can handle multiple workpieces at the same time, and the processing time is short, which greatly improves the production efficiency.Because it does not use chemicals and does not produce pollutants such as waste water and exhaust gas, it also saves costs.