Introduction of Sandblasting Room

Steel structure Shot Blasting Machine manufacturers talk about the difference between surface treatment of sand blasting and shot blasting, shot blasting has high efficiency, but there will be dead corners, and sand blasting is more sensitive, but the power consumption is large. Sandblasting and shot peening are two distinct surface hardening processes, each serving unique purposes. While shot blasting technology is known for its ability to enhance the hardness of materials through the use of high-energy impacts, sandblasting operates at a lower hardness level.

One of the key advantages of a sandblasting room is its simple structure, which allows for easy setup and operation. The initial investment required to establish a sandblasting booth is relatively low compared to other surface treatment facilities. Additionally, the sandblasting room features few wearing parts, which translates to lower maintenance costs over time. This cost-effectiveness makes it an attractive choice for businesses looking to optimize their surface treatment processes without incurring excessive expenses.

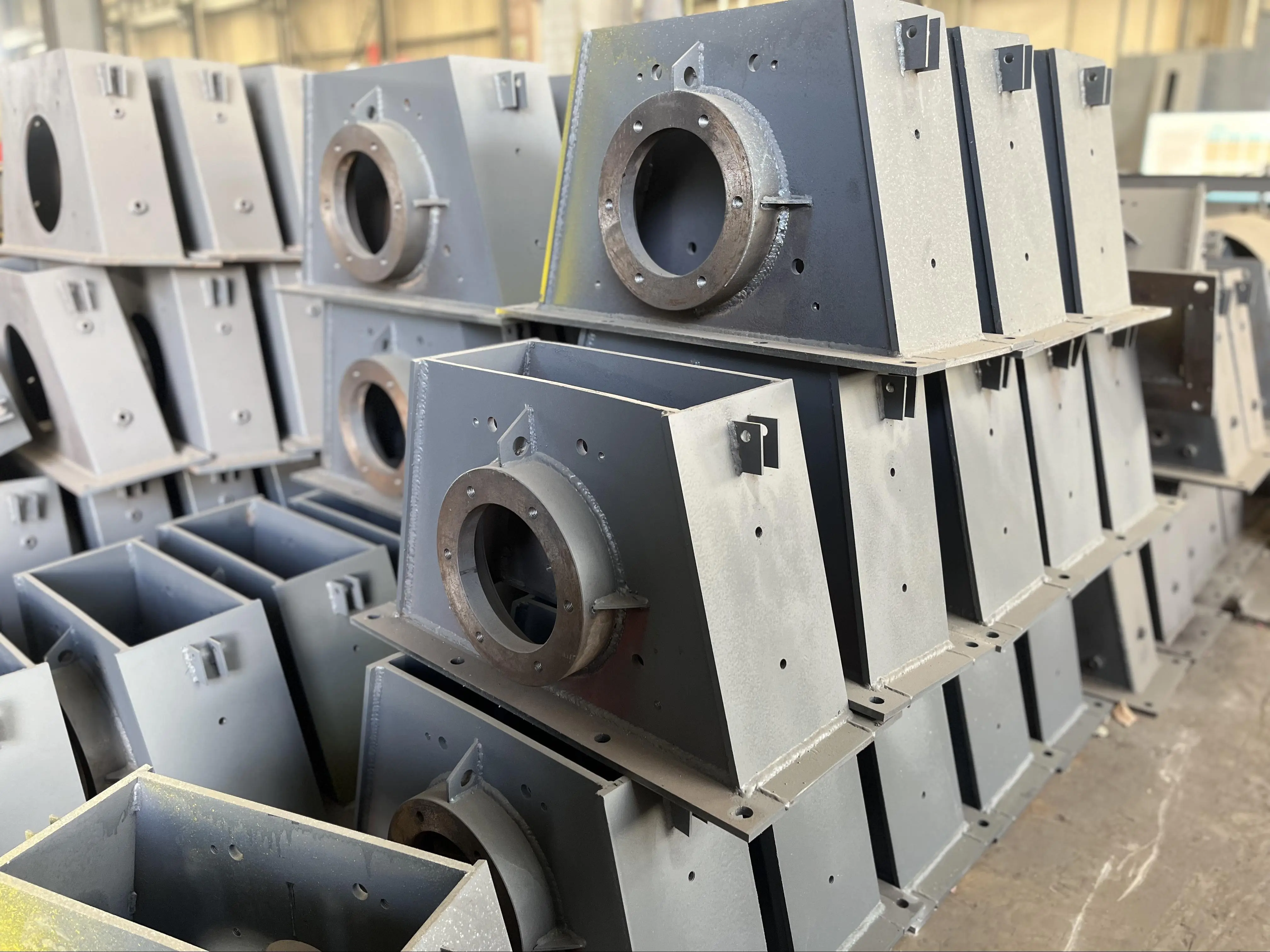

The sand blasting room is mainly composed of sand blasting room, sand blowing room, sand blasting system, abrasive recovery system, cyclone separator, Dust Collector and corresponding electrical pipeline components. The sand blasting chamber is welded by cold rolled steel plate, the inner and outer surfaces are sprayed with plastic, and the inner walls of the chamber are lined with maintenance rubber to prevent the sandblasting chamber from being easy worn.

Dust curtains are set on both sides of the blowing room to prevent dust leakage. The sand blasting system can choose frequency conversion speed regulation. After the parts is completed in the sand blasting room, it enters the sand blowing room, and the sand blowing room is arranged with air gun, which can blow the sand material on the surface of the parts into the sand hopper for recycling.

The sandblasting room is a vital component in the realm of surface treatment, offering a cost-effective, versatile, and efficient solution for various industrial applications. Its simple design and adaptability make it an essential tool for businesses aiming to enhance their production processes. The versatility of the sandblasting room is further enhanced by its ability to accommodate both metal and non-metallic projectiles. This flexibility allows operators to tailor the abrasive materials used based on the specific requirements of the part surface, ensuring optimal cleaning and finishing results. Whether it’s preparing metal components for painting or etching designs onto glass, the sandblasting room proves to be an invaluable asset in achieving high-quality surface finishes.