The development trend of shot blasting machine

Recent innovations in Shot Blasting Machine design have made the technology even more effective. Modern machines are equipped with advanced control systems that allow for precise adjustments in the intensity and direction of the blasting process. This ensures a more uniform finish and greater control over surface treatment parameters. These advancements not only improve the speed of operations but also optimize the consumption of abrasive materials, making the process more cost-effective.

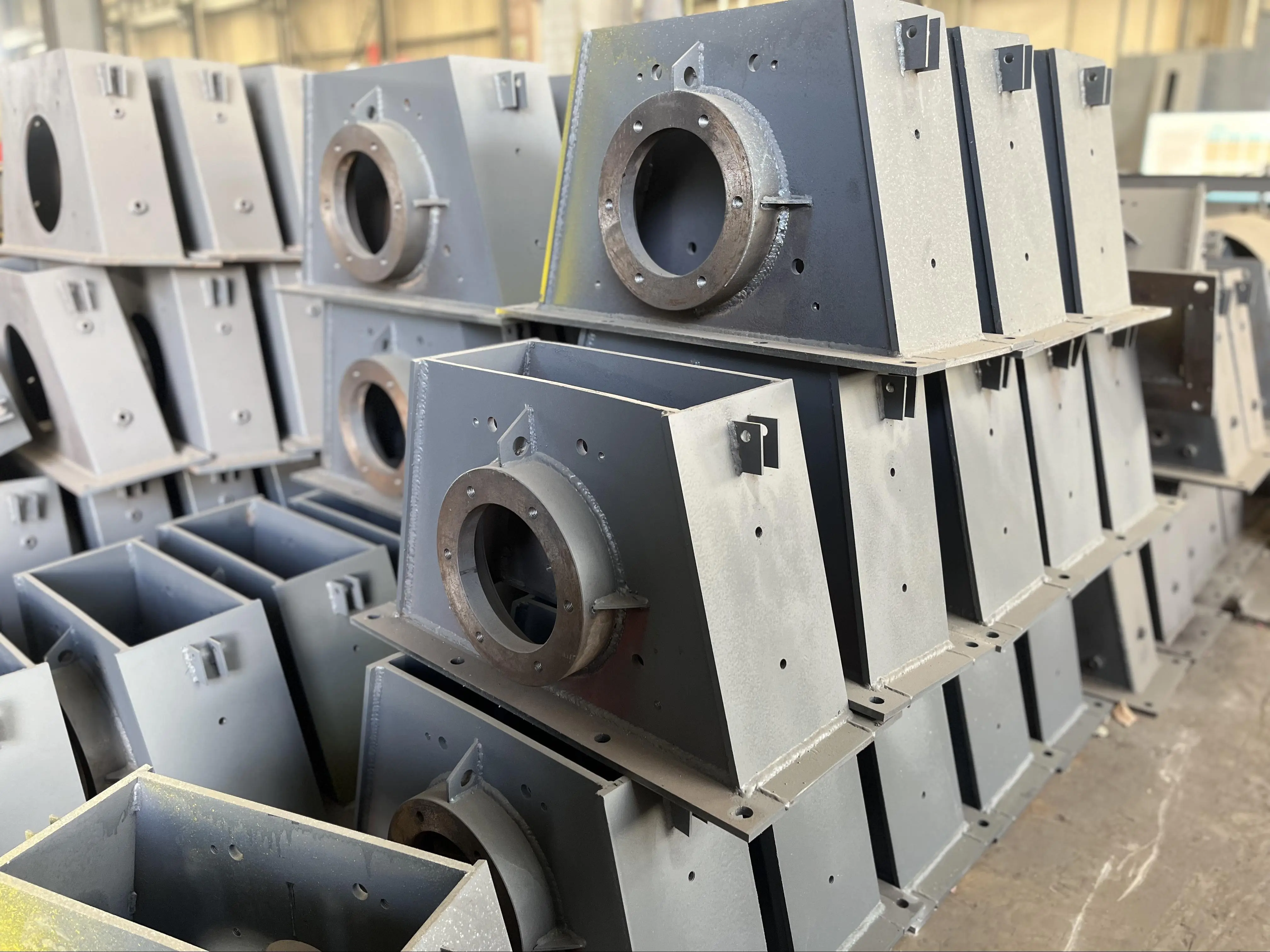

Some of the most common types of shot blasting machines:

1、Tumble Blast Machines: Designed for smaller parts or bulk materials, these machines tumble the parts inside a rotating drum, allowing the abrasive to clean the entire surface evenly.

2、Hook Type Blasting Machines is divided into single and double hook shot blasting machine: Ideal for larger parts, these machines suspend the items on hooks while abrasive is blasted at them. This type is perfect for processing heavy-duty components like automotive parts or steel structures.

3、Rotary Table Shot Blasting Machines: Featuring a rotating table, these machines are used for large volumes of parts, providing a high throughput rate. The rotation helps ensure even coverage of the blasted surface.

4、Pass Through Shot Blasting Machines: Suitable for cleaning various metal workpieces,Including steel castings、aluminium casting、forge piece、Cast iron.This kind of equipment can remove the oxide on the surface of the workpiece、rusting、oil contamination、Welding slag and attachments,The surface of the workpiece is cleaned.

Shot blasting machine Sustainability and Future Trends :

The future of Shot Blasting Machines looks promising, with trends leaning toward greater energy efficiency and sustainability. Modern machines are designed to minimize energy consumption and maximize abrasive reuse, which not only reduces costs but also supports eco-friendly manufacturing practices. As industries continue to push for greener solutions, the evolution of shot blasting technology will likely include even more environmentally friendly features, such as dust control systems and recycling capabilities.

Shot Blasting Machines have undoubtedly revolutionized the surface treatment industry, and their impact continues to grow. With continuous technological advancements, these machines not only enhance the efficiency of the manufacturing process but also help meet the increasing demand for high-quality and durable products. Whether in the automotive, aerospace, or construction industry, shot blasting machines remain an indispensable part of surface preparation.