The Introduction And Application Of Sandblasting Room

The working principle of the Sandblasting Room is mainly based on the two major systems of sandblasting and recycling,When the sandblasting system is working,The sand is stored in the sand-blasting tank, pressed out by a combination valve and sprayed to the workpiece surface at high speed by the sand-blasting gun.The recovery system uses the floor sand return technology or mechanical device to pick up the scattered sand and transport it through the pipeline to the sand dust separator for separation and dust removal.The separated useful sand is re-recycled,Useless debris is filtered。

The Sandblasting Room has the characteristics of high cleaning efficiency, good treatment effect, environmental protection and safe operation.

From a cleaning perspective,The cleaning efficiency of the Sandblasting Room is far more than that of the traditional manual cleaning method,It can reduce labor intensity,Improve production efficiency。From the processing of the workpiece effect above,By changing the type and particle size of the sandblasting material,You can get different surface states,Meet the processing needs of various complex workpieces。Most sandblasting houses are now equipped with dust collection systems,It can reduce environmental pollution.

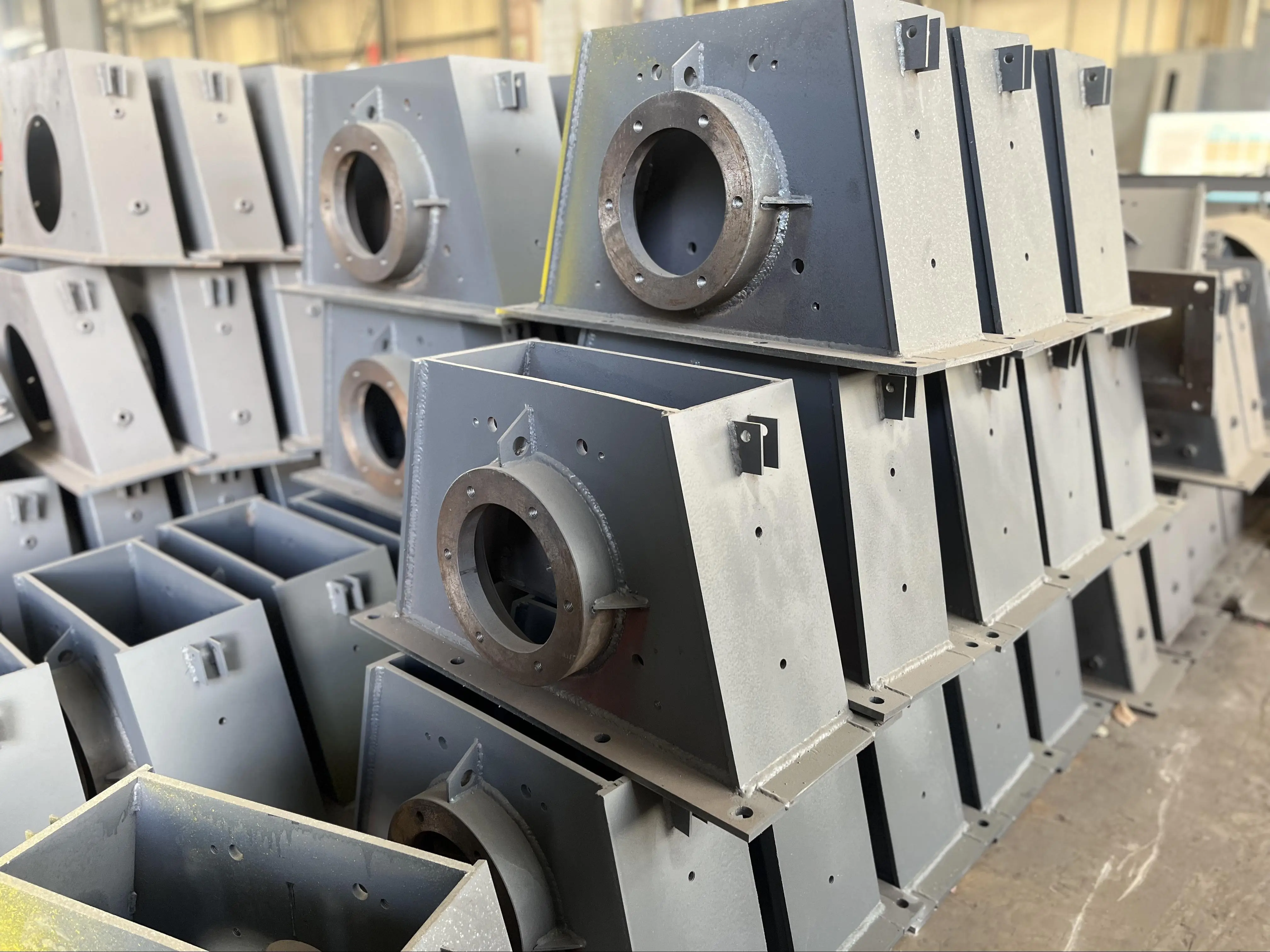

Sandblasting Room is widely used in large-scale workpiece surface cleaning, rust removal, increasing the adhesion between the workpiece and the coating and other scenarios.It is especially suitable for the surface treatment of steel structural parts, welding parts and casting workpieces,It can significantly improve the surface quality and adhesion of the workpiece,In addition,The design of the sandblasting room should consider the requirements of normal painting operation in all weather and trouble-free operation of process equipment at full load for a long time,To ensure efficient and stable operation。