Why the shot blasting machine is a cold processing process

Multiple depressions are stacked to form a uniform layer of residual compressive stress, which further enhances the hardness and fatigue resistance of the part, significantly extend the service life of the part. The surface of the newly cast casting will have some burrs and clay sand, which needs to be polished and anti-rust treatment. Some defective products also have pores on the surface, which has security risks for the use of the product, so it is required to check the surface of the casting, and the Shot Blasting Machine can well meet the above requirements.

The castings are moved to the shot blasting chamber by hook, rotation crawler belt or roller conveyor, and the casting is continuously rotated and rolled in the chamber while shot blasting.

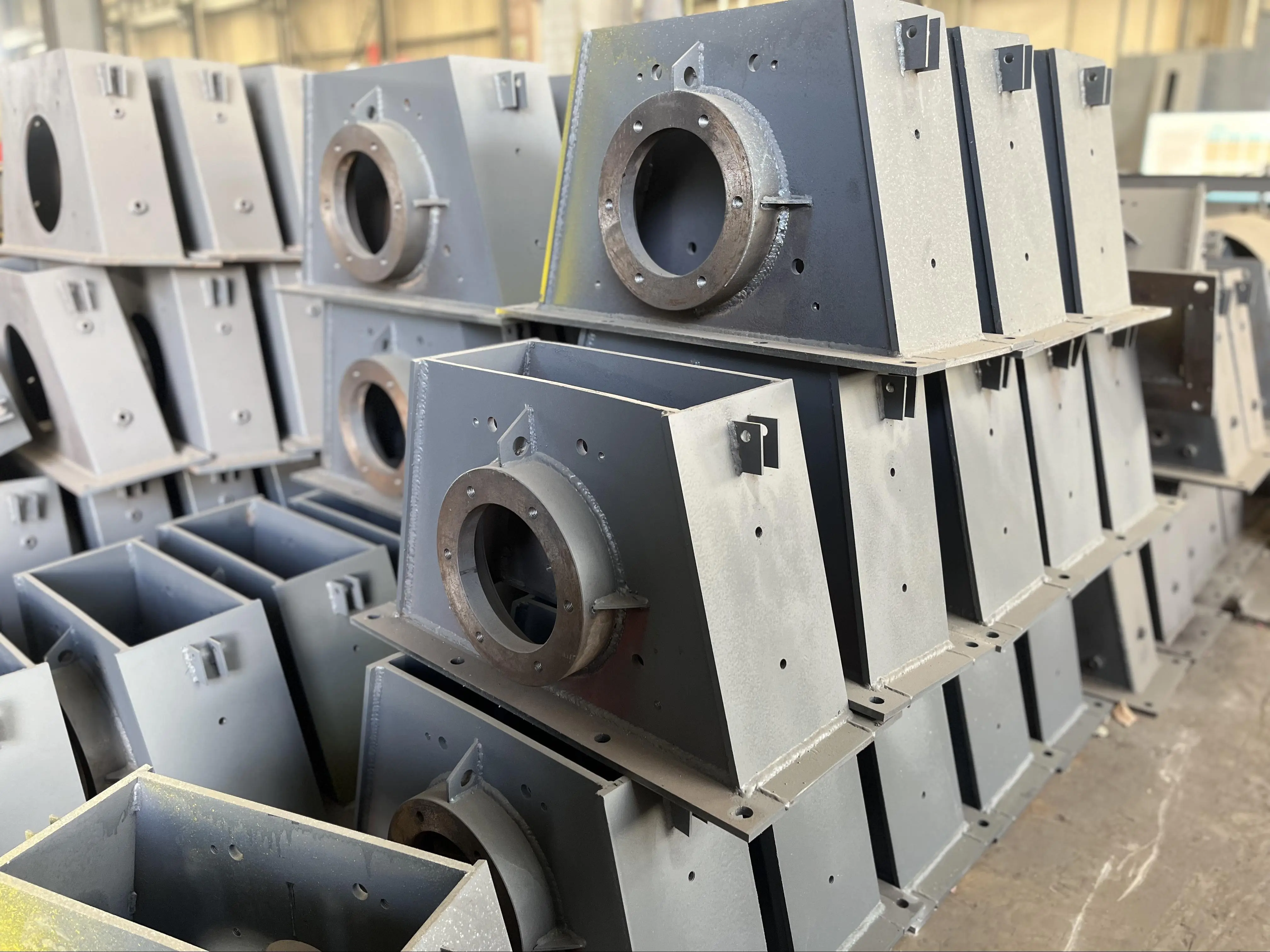

The shot blasting wheels are installed around the main chamber of the shot blasting machine, which can accelerate the shooting of the metal projectile. After the violent metal projectile impact, the defective castings can be screened at the same time, and the porosity is exposed early to avoid potential security hazards in the later stage. The abrasives impacts in all directions on the surface of the casting to remove the corrosion, scale and dirt on the surface of the casting, so that the casting reaches the purpose of rust prevention and rust prevention.