Xinke introduces new sand blasting booth

Sand blasting booth rooms are used for cleaning, polishing, and surface treatment of materials such as metals, plastics, and wood. The process involves spraying abrasive particles (such as silica sand) at high pressure to remove surface dirt, oxidation, rust, or to roughen and polish the surface. Xinke specializes in providing efficient and professional sandblasting booth solutions, catering to the needs of various industries and helping clients achieve superior surface treatment results.

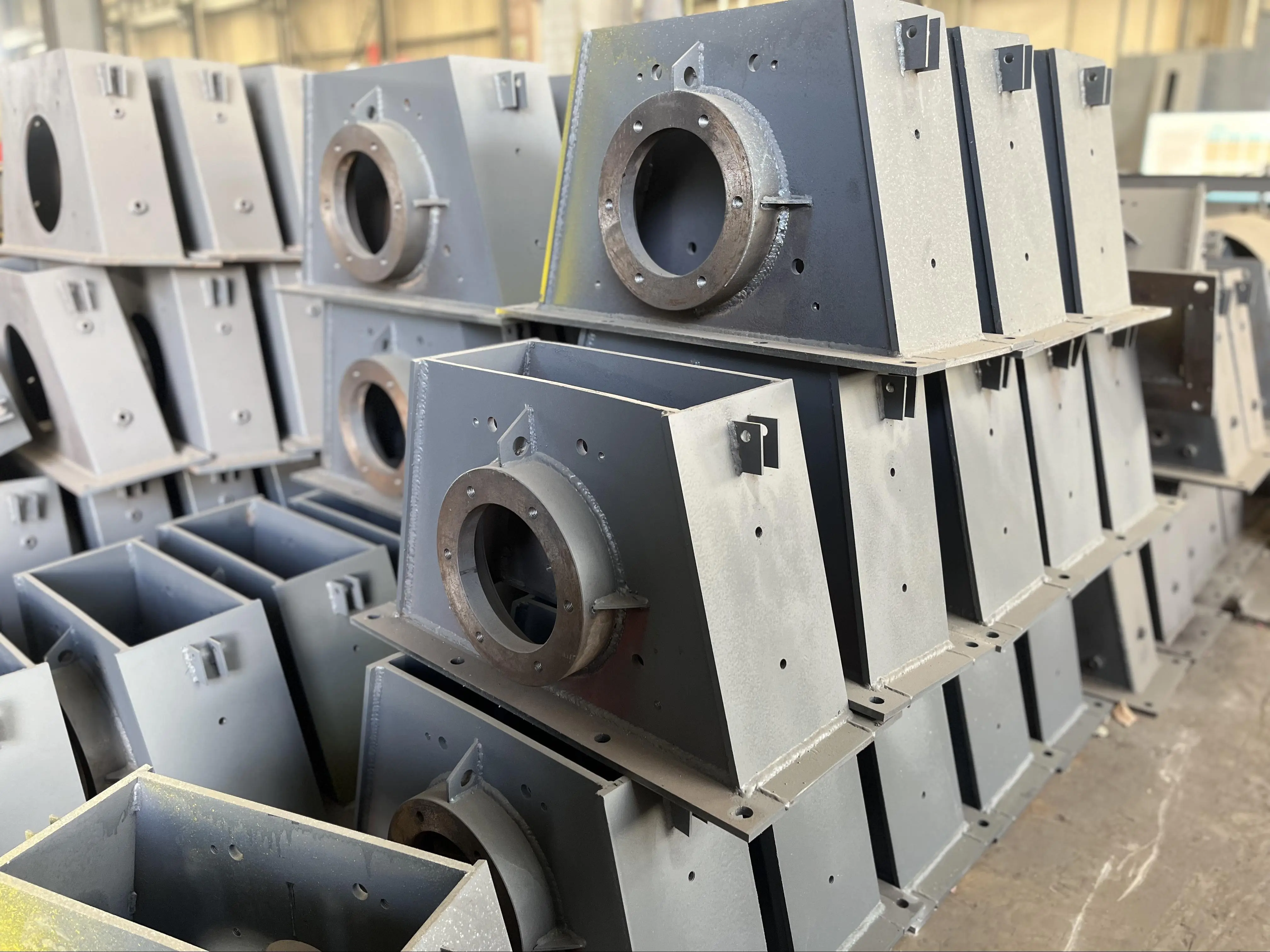

The basic principle of a sandblasting booth/room is to accelerate abrasive particles and spray them at the surface of the material. The impact of the particles on the surface removes contaminants and smoothens the surface. These systems generally consist of a sandblasting system, a dust removal system, a control system, and safety devices. The sandblasting system guides the abrasives through nozzles toward the workpieces, the dust removal system ensures clean air, preventing dust from harming the operators, and the safety devices protect the operators during use. Xinke provides a variety of customized sand blasting booth solutions according to client needs, ensuring that the surface treatment process is efficient and precise while meeting various industrial standards.

Sandblasting machines are highly effective in cleaning metal surfaces, removing rust, oxides, and oil stains, and are particularly suitable for materials like steel. Sandblasting not only smoothens metal surfaces, preventing the spread of rust, but also extends the lifespan of components. Additionally, sandblasting is used for surface roughening, especially before coating, where it enhances the adhesion of the coating and prevents peeling. Xinke sandblasting machine technology excels in improving coating adhesion, making it widely applicable in industries like automotive, shipbuilding, and construction.

Sandblasting booths are also used for polishing metals, plastics, and other materials to achieve aesthetic effects. Different abrasives with varying particle sizes and pressures can produce surfaces with different levels of gloss. At the same time, sandblasting is crucial in mold cleaning, particularly in casting industries. It is effective in removing residual sand and impurities from castings, ensuring the cleanliness and quality of molds. Xinke offers sandblasting booth equipment specially designed for the casting industry, helping clients increase production efficiency while ensuring precision in every product.

Despite the many benefits of sand blasting booths, there are some precautions that must be taken. First, sandblasting generates large amounts of dust, so an effective dust removal system must be in place to protect the health of operators. Additionally, Sandblasting Equipment, such as nozzles and pipes, should be regularly inspected to prevent wear or blockages that could reduce efficiency. Operators must also wear protective gear, including masks, gloves, and goggles, to prevent abrasives from causing harm. Xinke places great emphasis on equipment safety and provides detailed user instructions and strict safety protocols to ensure that clients can operate their equipment efficiently while safeguarding the well-being of workers.

In addition to standard fixed systems, retractable spray paint booths/rooms are an innovative solution for businesses that need flexibility. These retractable spray paint booths/rooms allow easy adjustments in space usage and can be moved or retracted to adapt to various operational needs. Xinke offers such retractable spray paint booth/room designs that integrate the latest technologies in sandblasting and painting, providing an all-in-one solution for surface treatment.

For industries needing portability, portable sandblasting booths provide a convenient solution. These mobile booths are easy to transport and set up, making them ideal for on-site operations where large, fixed equipment is impractical. Xinke portable sandblasting booth solutions offer clients the ability to perform sandblasting treatments in various locations, ensuring that no matter the job site, high-quality surface treatment can still be achieved.

In conclusion, sandblasting booths and sandblasting machines are essential surface treatment equipment used in metal cleaning, surface roughening, polishing, and mold cleaning across many industries. As technology advances, the functionality and design of these systems continue to improve, and they are expected to play a key role in an increasing number of industries. Xinke is committed to innovation and strives to offer clients efficient, environmentally friendly sandblasting equipment and comprehensive surface treatment solutions.