Product News

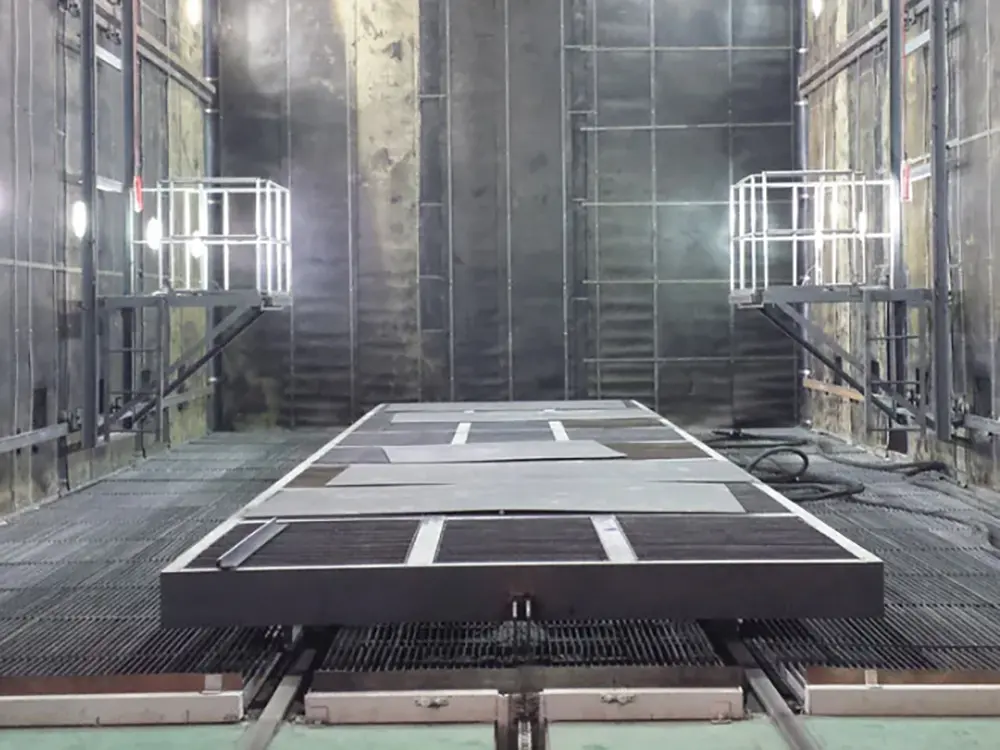

The Introduction And Application Of Sandblasting Room

Sandblasting Room is a kind of equipment for industrial cleaning and surface treatment,It is mainly used to shoot fine abrasive (such as sand, glass beads, steel balls, etc.) through high pressure jet stream to remove surface dirt, oxides, coatings and marks,This process is called sandblasting or shot blasting,It's a surface treatment technique,It is usually used to prepare the coating or bonding of metal, glass, ceramic and other surfaces,Or improve surface quality and strengthen parts in industrial manufacturing.

Introduction of Dust Removal System

A Dust Collector is a device that separates dust from flue gas,Mainly used in various industries production environment,Its performance is mainly determined by the amount of gas that can be handled、The gas is measured by the resistance loss and dust removal efficiency of the dust collector,In addition,The price of the dust collector, the cost of operation and maintenance, the length of service life and the difficulty of operation management are also important factors to consider its performance.

Introduction to road type shot blasting machine

Road Shot Blasting Machine is a kind of mechanical equipment specially used for road surface treatment,It is mainly used to improve the roughness and friction coefficient of the road surface,Thus enhancing the skid resistance and service life of the road surface。

Its working principle is to shoot the projectile onto the road surface through a high-speed rotating shot blasting wheel,Make the impurities on the road surface be effectively removed,At the same time, the pellets and impurities are recovered by the dust collector,Realize dust-free construction。

Application field and market prospect of shot blasting machine

The Shot Blasting Machine is not only used to remove the rust layer and oxide on the surface of the steel,It is also widely used in surface treatment of various industrial products.For example,Steel structure shot blasting machine is mainly used for steel plate, metal structure parts, machine tool bed, etc.Through strong shot blasting,Make the steel surface to obtain uniform metallic luster, improve the finish quality and anti-corrosion effect.

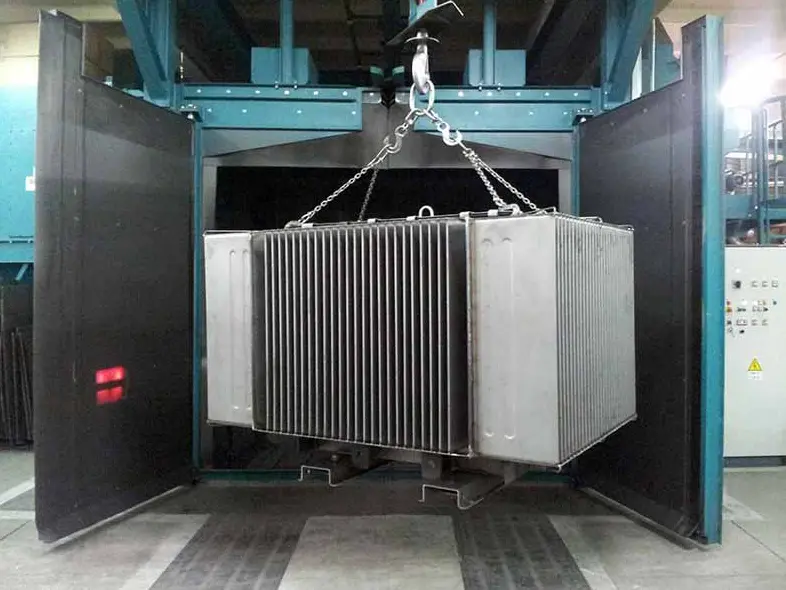

The Introduction Of Pass Through Shot Blasting Machine

Pass through shot blasting machine is a kind of mechanical equipment for metal surface treatment, mainly used for removing steel surface oxide, rust layer and dirt,The working principle is that the shot blasting particles are shot onto the surface of the workpiece through a high-speed rotating shot blasting device, and the impact force and cutting action of the shot blasting particles are used to remove the impurities on the surface of the workpiece, while increasing the surface roughness and improving the adhesion of the coating.

Hook type shot blasting machine working principle

The working principle of the hook type shot blasting machine is to drive the shot blasting machine wheel to rotate at high speed through the motor, spray the metal projectile to the surface of the workpiece, remove the dirt, oxide and other impurities on the surface through impact and friction, and enhance the hardness and corrosion resistance of the workpiece。

Basic Functions of Catenary Shot Blasting Machine

Catenary shot blasting machine has high productivity and reliable operation. It is very suitable for mass cleaning of all kinds of hangable parts, including cast steel, cast iron, and welded parts, such as engine cylinder head, motor housing, gear, motorcycle engine housing, locomotive hook tail frame, bogie part, hardware tool housing, water pump, etc. This makes it suitable for industries that require thorough cleaning of complex shapes and sizes, ensuring that all surfaces are adequately prepared for subsequent processes such as painting or coating, it can be designed and produced according to user product requirements.

How to Improve the Performance of Hook Shot Blasting Machine

The hook shot blasting machine is an essential equipment in various industries, particularly for surface preparation and cleaning of metal components. To enhance its performance, it is crucial to address several factors, including dust management, operational efficiency, and maintenance practices.

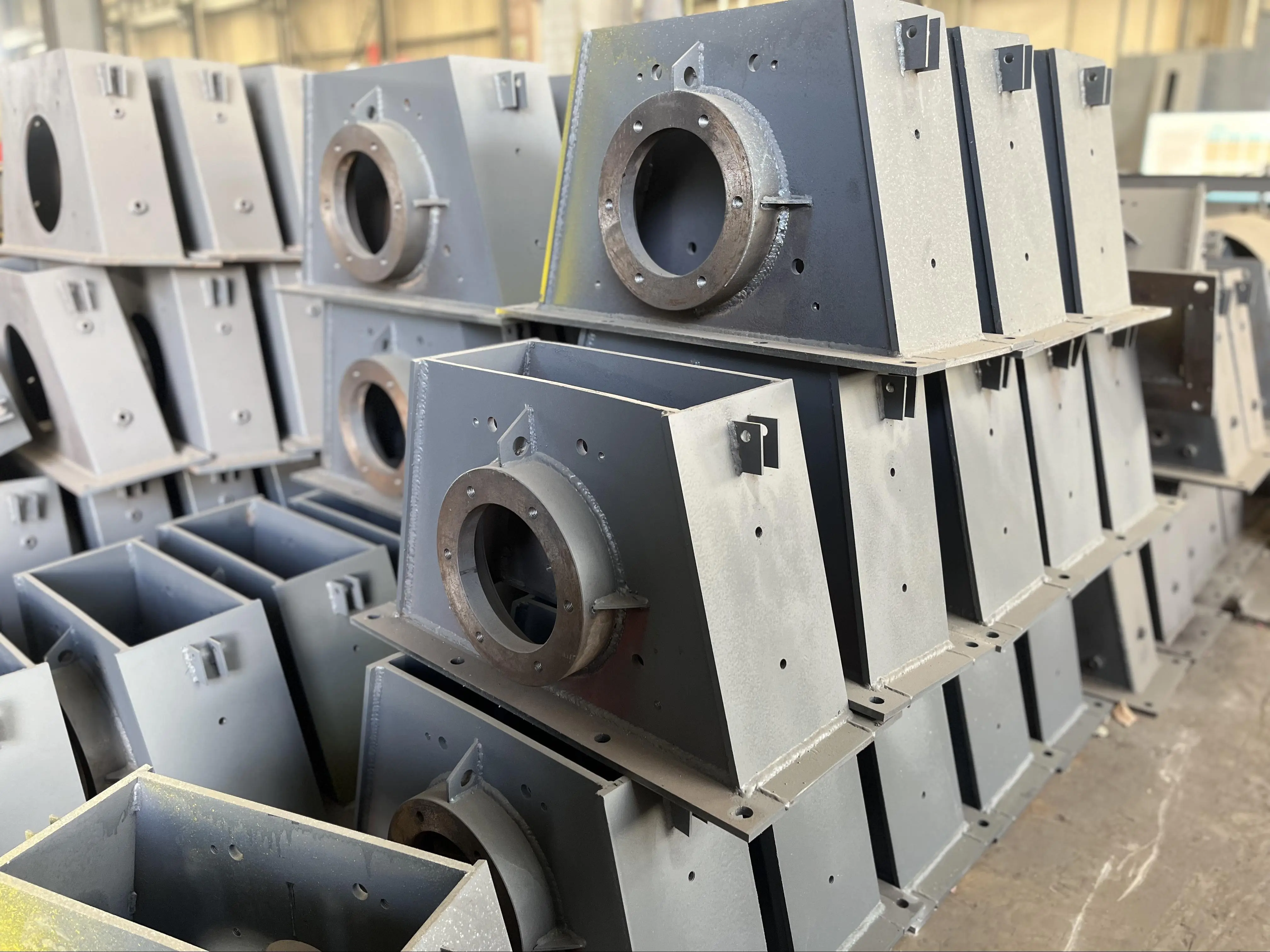

Introduction of Sandblasting Room

A sandblasting room, often referred to as a sand blasting booth, is an essential facility in various industries for surface preparation and finishing. This specialized environment is designed to facilitate the sandblasting process, which involves propelling abrasive materials at high speeds to clean, smooth, or etch the surface of various parts.

High efficiency Large Steel Strip Pretreatment Machine

In the ever-evolving landscape of industrial manufacturing, the importance of effective surface treatment processes cannot be overstated. One of the most efficient methods for preparing steel surfaces is through the use of shot blasting machines. Qingdao Xinke Machinery is a professional production and custom all kind of shot blasting machine enterprises.