Product News

Why does the turbine blade surface appears groove-like wear?

The surface of turbine blade appears groove-like wear, which should be turned around immediately, and then replaced with a new blade. Because the wear occurs in the outward-facing part of the blade (shot ejection area) and the inward-facing part (shot suction area) is subjected to a small degree of wear.

Why the shot blasting machine is a cold processing process

The Shot Blasting Machine is a cold working process which the turbine driven by motor and continuously hits the surface of the part with small steel abrasives. Each steel shot hits the surface of a metal part and pulls out small dents or dents in a small rod. To form a depression, the metal surface layer is stretched. Beneath the surface layer, the condensed particles attempt to restore the surface to its original shape, resulting in a hemisphere with high compacting forces.

How to solve the problem that the hook shot blasting machine not feeding?

Hook type shot blasting machine chamber is spliced with multiple high wear-resistant guard plate, The hanger shot blasting machine usually designed according to the rotating diameter and height of the cleaning item.

Performance characteristics of shot blasting machine

Shot blasting machines can used to remove burrs, diaphragms and rust that may affect the integrity,appearance or definition of the part of an object.

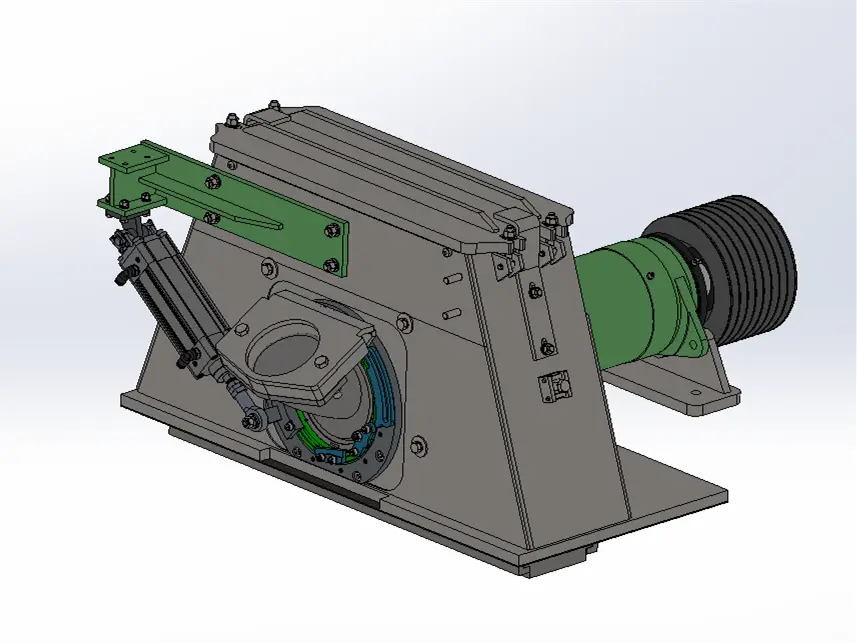

The working principle of turbine shot blasting machine

Many steel, parts due to the placement process, from time to time with moist air contact, produced a series of chemical reactions, accumulated in the appearance of a layer of oxide and rust, the use of its aesthetic and deep processing disposal has a negative impact, at this time the application of shot blasting machine to stop the shot blasting rust disposal is particularly important.

Crawler shot blasting machine installation precautions

The working principle of the crawler shot blasting machine is to put a certain number of items into the shot blasting chamber, and then close the door, and then machine starts, the cleaning items are driven by the crawler belt to rolling. At the same time, the abrasive thrown out by the high speed turbine forms a fan-shaped beam and evenly hits the surface of cleaning items.The abrasives and crushed particle flow through small holes in the crawler belt into the screw conveyor, and then fed into the bucket elevator and separator.

The application field of Steel structure shot blasting machine

Steel structure shot blasting machine is mainly used in steel plate, metal structural parts, machine tool bed, steel (cast iron) products, grid, construction machinery and bridge manufacturing. The pass through type roller conveyor shot blasting machine can apply shot blasting to the original steel surface to remove the rust layer and oxide on it, so that it can obtain a uniform metallic luster, so as to improve the coating quality and anti-corrosion effect of steel.

Characteristics of Steel plate pretreatment line

The Steel pretreatment line process refers to the steel before processing (i.e., raw materials) in surface blasting derusting and processing technology of coated with a layer of protection primer.

The correct operation method of Crawler shot blasting machine

The Crawler shot blasting machine is commonly used in small and medium-sized enterprises, suitable for cleaning some small workpieces, it can be used with production lines. There are two kinds of crawler belt shot blasting machine: Rubber belt shot blasting machine and metal belt shot blasting machine. According to the demand of production capacity, different sizes of shot blasting models and degree of automation can be selected.

What are the applications of Portable shot blasting machine?

Now more and more customers choose to use the portable shot blasting machine for cleaning bridge and road surface. The portable shot blasting machine is small and light, and the cleaning process can be easily handled by one person.