Product News

What are the wrong operations of the shot blasting machine?

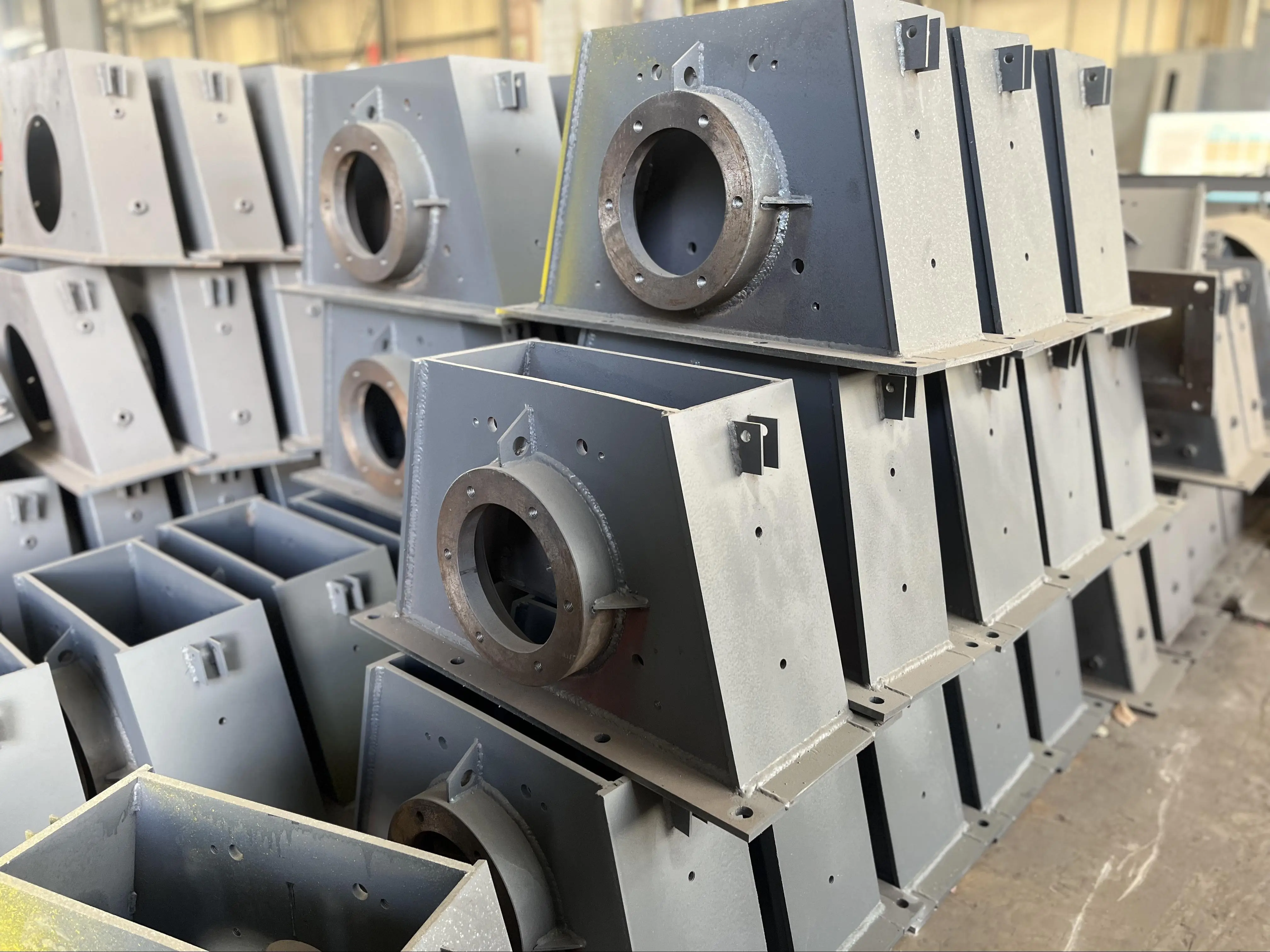

Shot Blasting Machine is a kind of machine equipment for cleaning the appearance of steel casting parts such as steel sand and steel shots, and the application of shot blasting machine has been very common in the work production, and there are special targeted training for the staff operating the shot blasting machine to prevent accidents in the process of using the shot blasting machine.

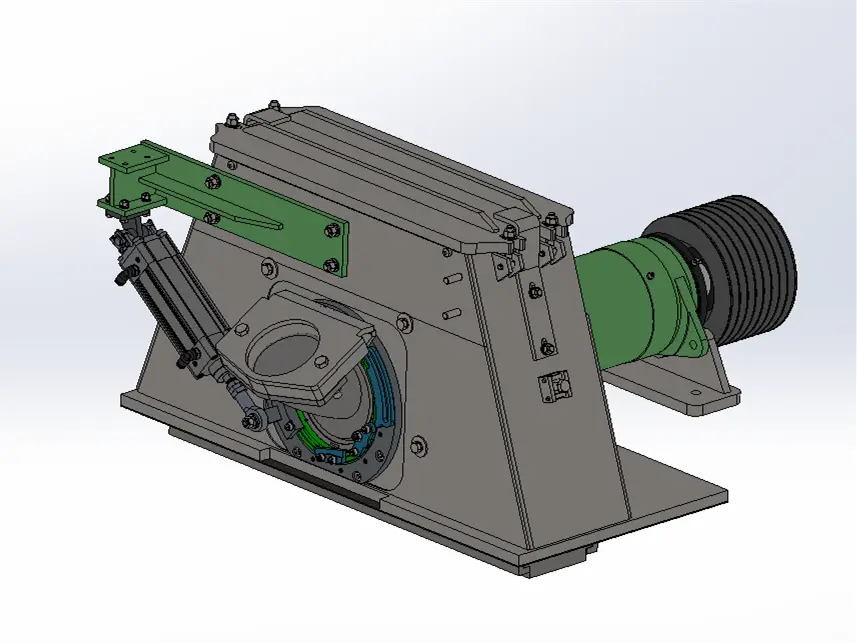

Two kinds of connection methods of shot blasting head

In the realm of surface treatment technology, shot blasting machines have become indispensable for enhancing the quality and durability of various components. Xinke shot blasting machine fully demonstrates the high efficiency and effectiveness of modern shot blasting technology. This innovation highlights the growing importance of advanced machinery in manufacturing, particularly in achieving superior surface finishes and preparing components for further processing.

China Leading Hook Shot Blasting Machine- Qingdao Xinke Machinery

Qingdao Xinke’s innovative to shot blasting machine, represents a new era in foundry technology.

With customizable features and a rugged design, the hook-type shot blasting machine demonstrates the potential of modern Foundry Equipment.

As the industry continues to evolve, embracing these cutting-edge technologies is essential for foundries looking to stay competitive in a rapidly changing market.

Revolutionizing Manufacturing with Shot Blasting Machines

The role of shot blasting machines in the peening industry is pivotal, and at Qingdao Xinke Machinery, we are at the forefront of this technology. Our diverse range of machines, including the roller conveyor shot blasting machine, hook type shot blasting machine, tumble shot blasting machine, drum shot blasting machine and integrated shot blasting and painting systems, are designed to meet the demands of modern manufacturing.

Innovative V-Process Casting Technology by Qingdao Xinke Machinery

Qingdao Xinke Machinery Technology Co., Ltd. has announced a breakthrough in V-process casting, the third generation of physical molding methods. Originating in Japan in 1969, V-process casting simplifies mold making with unbonded sand and boasts high dimensional precision in casting, easy peeling, and a high sand return rate of 95%. After several decades of development, V-process casting has become a mature technology. Qingdao Xinke Machinery Technology Co., Ltd. has been at the forefront of this development, making significant strides in the industry. This breakthrough in V-process casting technology is expected to have a major impact on the casting industry, offering numerous advantages and further solidifying Qingdao Xinke Machinery Technology Co., Ltd.'s position as a leader in the field

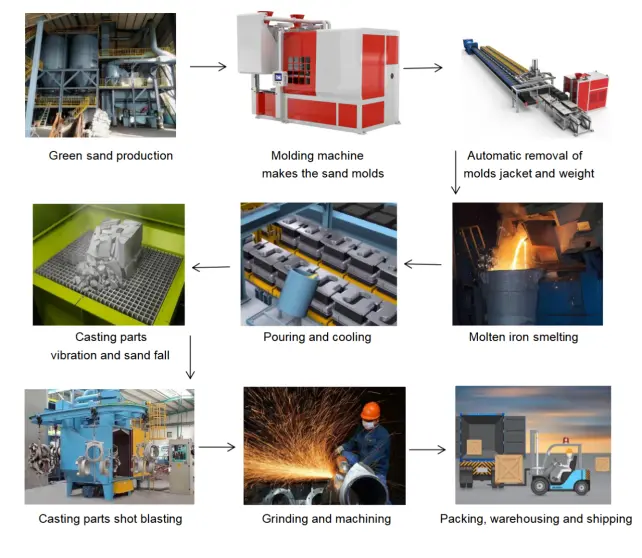

Introduction of Xinke Horizontal Parting Automatic Molding Machine

Qingdao Xinke Machinery Technology Co., Ltd. has revolutionized the traditional foundry model production with their automatic molding machine. The company has addressed the inefficiency and inconsistency of hand modeling, along with the limitations of producing large castings, by introducing this advanced technology. With the automatic molding machine, only one machine is required to complete a sand mold, significantly improving production efficiency and quality of castings. This innovation is set to modernize and optimize the foundry model production process, ensuring consistent and high-quality output.

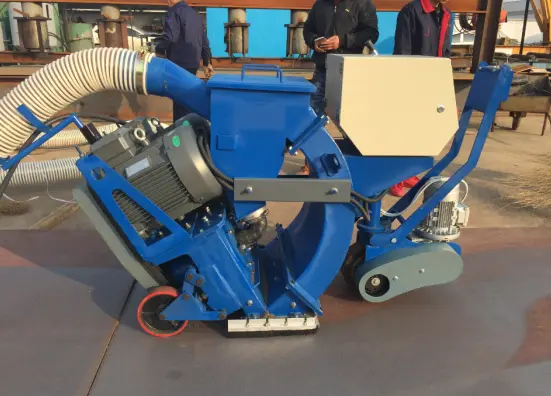

Portable shot blasting machine introduction

The portable shot blasting machine is a crucial equipment in modern road construction and maintenance, providing effective surface preparation by cleaning and profiling the surface.

Xinke introduces new sand blasting booth

Qingdao Xinke Machinery Technology Co., Ltd. is a leading provider of sandblasting booth solutions for various industries, offering efficient and professional services for cleaning, polishing, and surface treatment of materials such as metals, plastics, and wood. Their sandblasting booths are used for spraying abrasive particles at high pressure to remove surface dirt, oxidation, rust, or to roughen and polish the surface. With a focus on achieving superior surface treatment results, Xinke caters to the needs of clients by providing high-quality and reliable sandblasting booth rooms. Their expertise and dedication to excellence make them a go-to choice for businesses seeking top-notch surface treatment solutions

Advantages of the hook shot blasting machine

The hook-type shot blasting machine plays a crucial role in metal surface treatment, particularly for cleaning and rust removal. Its efficiency and effectiveness set it apart from traditional methods, making it a popular choice across various industries. This industrial shot blasting machine operates using mechanical action, effectively removing surface oxides and rust from metal components. This process not only cleans the surface but also enhances its roughness, which is essential for improving coating adhesion and ensuring a durable finish.

The main application of hook type shot blasting machine

The hook type shot blasting machine is a widely utilized piece of equipment in the field of metal surface treatment. Its primary function is to clean the surfaces of various workpieces by removing oxide scale, rust, and other contaminants through the application of shot blasting technology. This process is crucial for enhancing the durability and aesthetic appeal of metal products and is employed across numerous industries, including automotive, shipbuilding, aerospace, and machinery manufacturing.